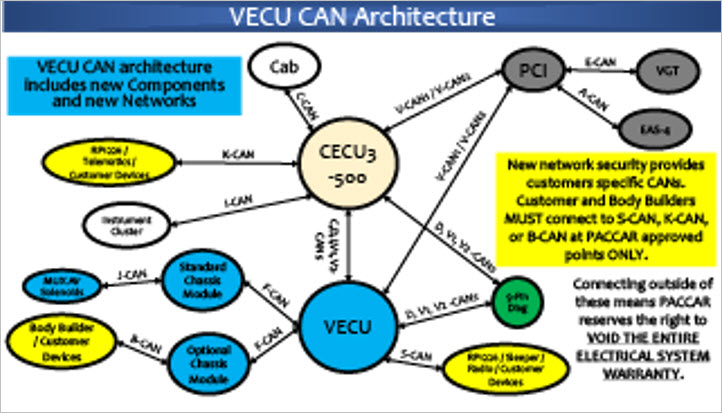

Kenworth runs multiple CAN (Controller Area Network) systems in both platforms. NGP trucks have migrated to the latest control system of CVMUX. Two modules control all cab and chassis functions using modules such as the SCM (Standard Chassis Module) to control functions like lighting and electric over air systems. 1.9M cabs run NAMUX 3 or 4 system depending on the year. NAMUX systems run a single control module with a chassis module, again year dependent.

Kenworth has taken the stance if you plug into their network and your addition causes fault codes they are not responsible. This includes plugging an ELD into the 9 pin and applies to NGP trucks. We have had several cases of the ELD causing noise on the CAN communication lines setting random fault codes; it is something to take seriously.

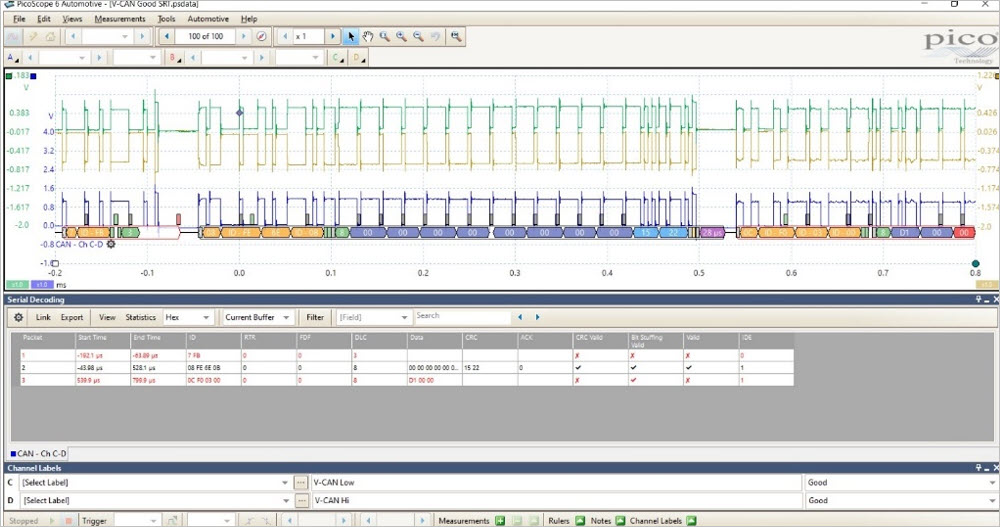

Let’s take a second and discuss CAN networks and their functions. You can think of CAN networks as high-speed communication lines where modules talk to each other at either 250KB/s (Kilobits) or 500KB/s speed. These CAN networks follow SAE J1939 standards and have two 120-ohm resistors making circuit resistance 60 +/- 3 ohms between the twisted circuits. These modules relay information in almost real time using varying voltage signals. One line is CAN HI where the voltage is pulled up and the other is CAN LOW, the voltage is pulled down. HI and LOW are mirror images of each other when measured with an oscilloscope as shown below. Most CAN faults occur when data is missing that a module is looking for and does not see it for one second. Speaking as a technician, intermittent CAN faults are the hardest to troubleshoot. We can spend hours trying to locate the fault and sometimes never do.