April Tech Minute: Top 3 Turbocharging Tips for Your Truck

|  |

Turbochargers are very reliable: Less than 1% of turbochargers fail due to a manufacturing fault with the turbocharger itself. 95% of turbocharger failure are because of problems with oil starvation, oil contamination or foreign object damage. You'll most likely need to get your truck serviced when this happens! You may even need to replace some of your truck parts as well.

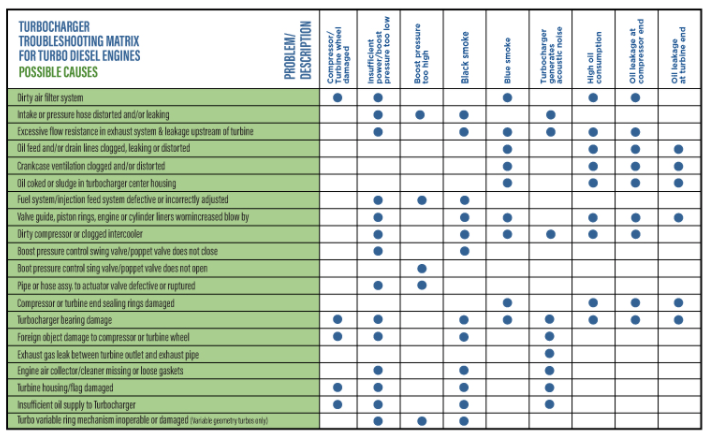

1. UNDERSTAND WHY ORIGINAL TURBOCHARGER FAILED:

- Contaminated Oil?

- Inlet/Outlet restriction?

- Foreign Impact Damage?

- Overheated?

2. DO THOROUGH PREPARATION:

- Verify Turbo Part Number & Application is correct

- Always replace oil/filters/Air Cleaner/Clean Air Cleaner Housing

- Change the Oil Inlet line as a standard practice

- Ensure that DPF Filter is clean and EGR Valve is functioning properly

- Verify that there are no Exhaust Muffler restrictions

- Crank the engine, without starting it to push out all old oil from oil feed Line

- Check All Lines/Hoses for cracks or chafing

- Check PVC system for restrictions and replace PVC Filter

3. PROPER INSTALLATION IS CRITICAL:

- Ensure that no dirt enters the oil or air paths of the Turbo

- All old gasket material must be removed/check Flanges for flatness to create proper sealing surface

- All O-rings and gaskets must be in place and correctly positioned

- Crank Engine for 15-20 seconds to prime oil feed to Turbo

- When Engine is first started, let idle for 3-5 minutes to warm up while you check for oil/air leaks/Coolant level

- •Verify Engine Oil Level is proper